Discover the exceptional artistry of our skilled metal craftsmen, who bring your design pieces and interior visions to life. With their expertise in techniques such as bronze casting, patinas, and modern technologies like CNC milling, they meticulously shape and manipulate metal with precision and creativity. Whether you desire intricate details, textured finishes, or precise cuts, our craftsmen have the mastery to fulfill your unique metal crafting needs.

- RAMSAY GROUP -

METAL

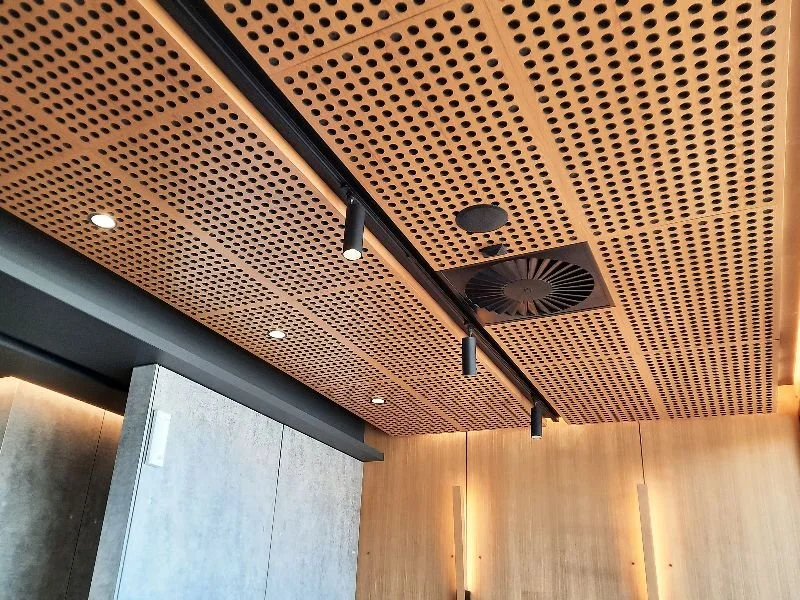

ARCHITECTURAL METAL

Metal has become more prevalent in residential and commercial architecture. Its reflective quality has broadened the scope of texture and color combinations, giving rise to a fresh aesthetic for interior design. Consequently, architects and designers increasingly incorporate metallic surfaces to define floors, benches, and other furniture elements, thereby defining spatial layouts and infusing them with a contemporary theme. To inspire this trend, we explore various methods for incorporating metal materials into your space.

WOVEN MATERIAL

Woven Metal is a specialised technique that combines the rich Italian textile tradition with innovation and research in Metal Textiles. Our focus has been on knitted metal fabrics, offering a diverse range of products for architecture, interior design, fashion, and EMI shielding materials. Our fabrics are crafted from materials such as brass, stainless steel, copper, and colored copper, ensuring both versatility and quality in our metal knitting creations.

LETS WORK TOGETHER.

If you have an idea, concept, technical design or would like to learn more about our architectural products, please contact us.

VARNISHING AND LIQUID METALS

Varnishing opens up a world of endless possibilities for achieving the desired finish, with options ranging from liquid metal to oxidation and power-coating. Liquid metal is a unique process of cold metalization applied through spraying, offering the ability to create stunning metal effects on surfaces such as metal, wood, or MDF. When applied to a textured substrate, it can beautifully replicate the look of metal casting, adding a touch of authenticity and sophistication to any project. With varnishing techniques like liquid metal, the potential for creativity and customization knows no bounds.

PATINATION

Patina is a thin layer of tarnish that forms on the surface of copper, brass and bronze as a result of oxidation or other chemical processes. The artisans intuitive and expert hands manage the chemical process by soaking, rubbing and drying each individual piece. The final colour is the result of a complex balance between chemicals and the time the metal has been exposed to them.

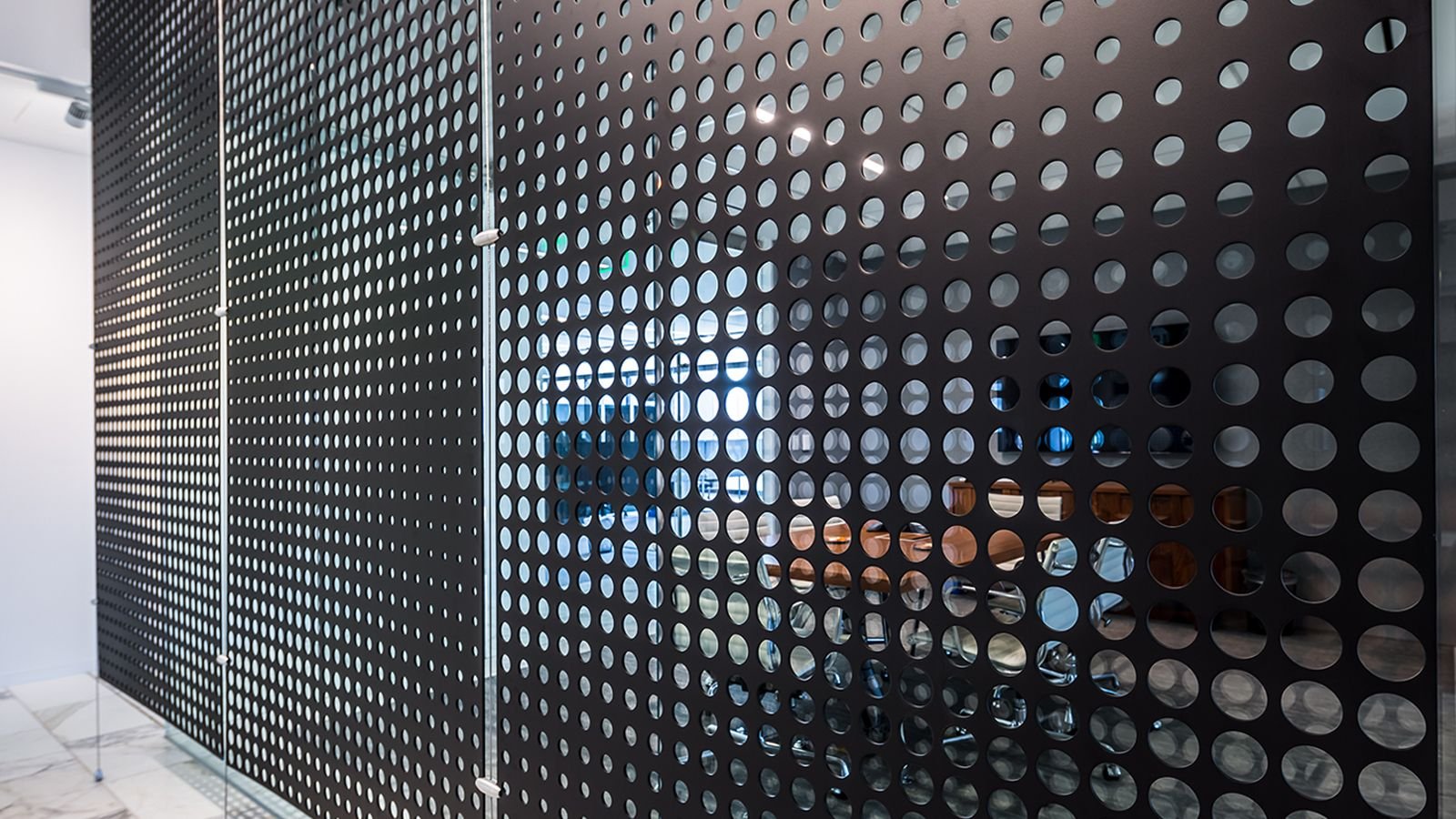

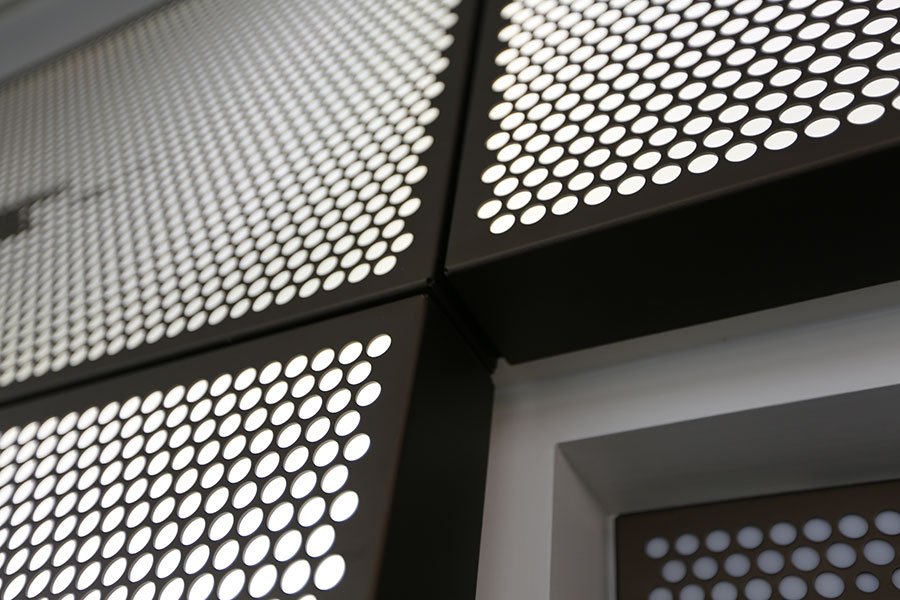

POWDER COATINGS

In architectural applications, our powder coatings can be applied to metal components and products to provide durability and resistance to scratching, fading, erosion or other types of damage that can ruin the aesthetics of a space.

Our powder coatings are made by melting resins, pigments and other additives together and grinding them into a fine powder, which can be formulated to provide a range of unique customised color options and surface finishes for products which is vital to the architecture industry.

METAL CASTING AND MOULDING

A technique that has stood the test of time since the 3rd millennium BC. Discover the fascinating variations of this art, from lost-wax casting to sand and die casting. In the process, hot molten metal is poured into a mold carefully crafted to mirror the negative shape of a wax model. As the metal flows in, the wax model is melted and drained away. To create a hollow core, a heat-proof core is introduced to prevent complete filling of the mold by the molten metal. Materials such as bronze, brass, aluminum, silver, and gold find their artistic expression through this ancient craft. Prepare to be captivated by the timeless artistry of metal casting.

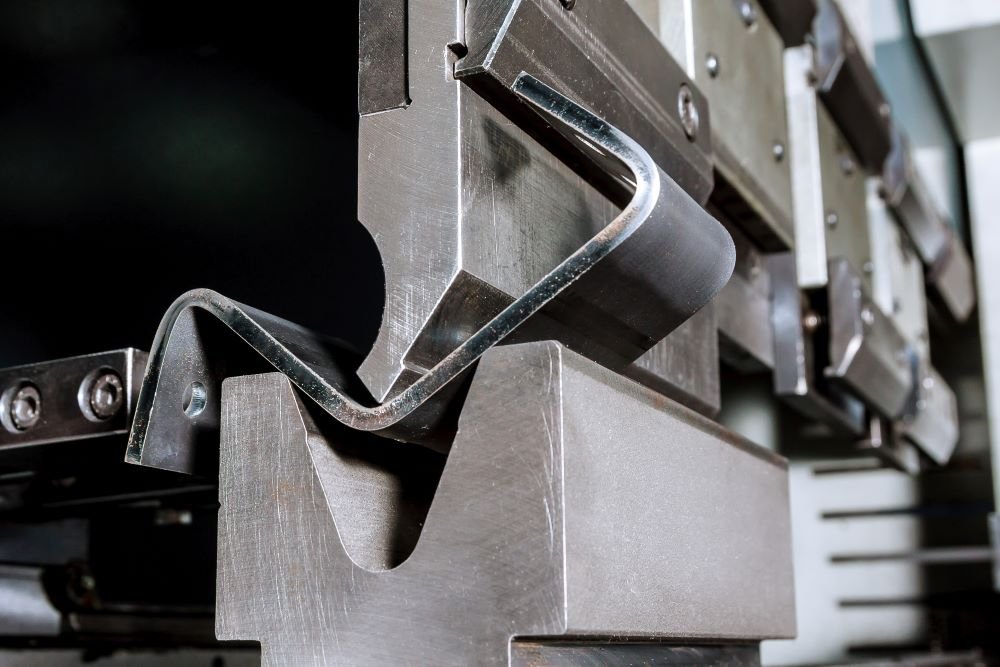

METALWORK MACHINERY

From metal forming to CNC milling, bending, turning, spinning, and calendaring, machines provide a vast array of techniques for working with the versatile material of metal. These processes enable the shaping, cutting, and manipulation of metal with precision and efficiency. Whether it's creating intricate designs, achieving specific dimensions, or enhancing the strength and functionality of metal components, these machine-based methods offer unparalleled versatility. Unlock the potential of metal and explore the limitless possibilities made possible by these advanced techniques.

BENDING AND FOLDING

These versatile processes allow for the formation of complex shapes using various types of ductile metal tubings or plates. Traditional machines utilise bending techniques to shape the workpiece according to the contours of a die, enabling multiple bends and angles. In the evolution of this method, computer-controlled bending takes center stage, employing CNC press brakes that can be programmed to execute precise movements and angles. This advancement in technology enhances efficiency and accuracy in the bending process, providing greater flexibility and control over the final product's shape.

Metal In Use . . .